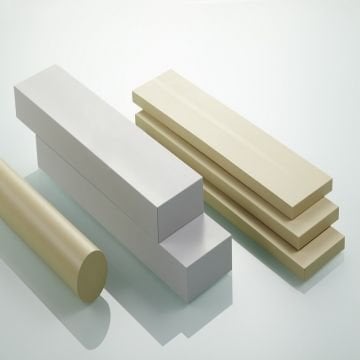

PA6 G YUVARLAK

PA6 G – Cast Polyamide

The production method of cast polyamide is by pouring caprolactam into the mold (polymerization).

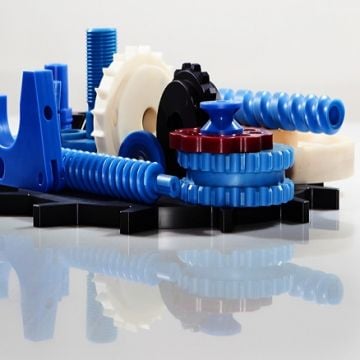

It is generally used for large gears and rings, o-rings or products with wall thickness. In terms of general properties, it is harder and more brittle (since it is stable) than extruded PA6. Its general properties are similar to PA66.6.

Even when working with metals (including friction), its wear resistance is high. Its properties are increased by some auxiliary (composite) materials (MoS2 molybdenum disulfide, solid oil, silicone, etc.).

Features

Wear resistance is high even in harsh environments.

Tensile stress, compressive strength and toughness (fatigue resistance) are higher than extruded PA6.

Thanks to its self-lubricating feature, no additional lubricants are required (low coefficient of friction).

Generally suitable for friction applications.

Ageing resistance is good in outdoor environments (-30 °C, +170 °C). All mechanical properties are better than PA 6. Generally, the operating temperature is between -30 °C and +100 °C.

Color: natural

Weak point

It is hygroscopic like extruded PA 6 and easily penetrates into water. It is preferred for large-scale parts, but it has high brittleness (stable; because its molecular structure is long) compared to extruded (drawn) PA6. Since its water absorption is higher than other engineering plastics, it causes problems in using it in aqueous environments (no dimensional stability). However, it is resistant to certain acids and alkalis.

APPLICATION

Mechanical : Large-scale materials are used to produce large-diameter gears, mechanical parts, keys, pulleys, wheels, wear plates, bearing bushes and wear-resistant guides.

Food contact : Generally not suitable for food contact.

Electrical : In terms of electrical properties, insulation value varies due to sensitivity to moisture.

Chemical : Resistant to alkali, inorganic compounds and solvents.

Water Absorption Percentages of Polyamides

This chart shows the percentage of moisture absorbed by Polyamides.

Yellow: 50% humidity in the air

Grey: Water is saturated