ALPOLEN UHMW 1000 PLATE

Very high molecular weight polyethylene UHMW 1000 material is highly resistant to abrasion and impact and can be used in a wide temperature range (-40 +80 °C). As the molecular weight increases; technical features such as internal strength, tensile strength at high temperatures, resistance to cracking and abrasion stress, excellent low temperature performance also increase. Due to its low coefficient of friction and high resistance to chemical effects, it is especially preferred in the food, textile and beverage industries. Being FDA compliant adds the feature of being able to come into contact with food.

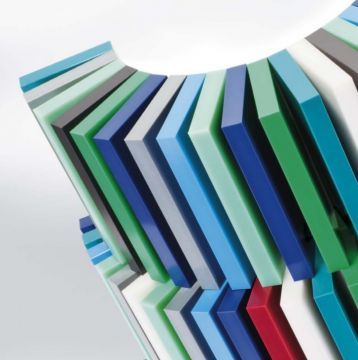

The products are in WHITE, GREEN, BLACK colors. Please ask for a price for white color.

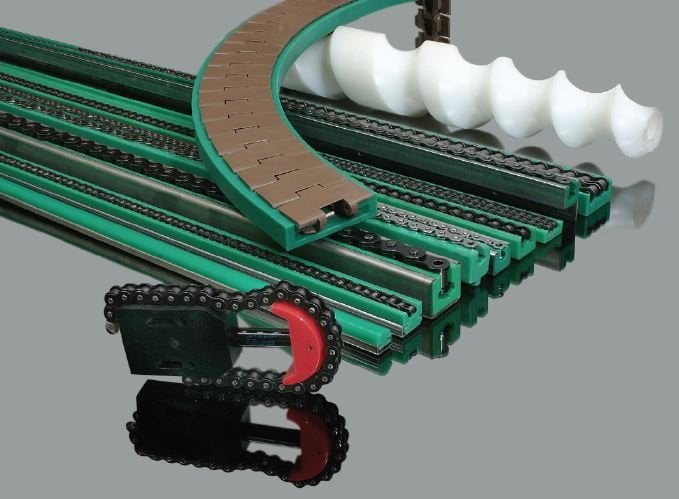

Alpolen UHMW 1000 applications for screw conveyors

Alpolen is a material with excellent compression strength known to have a molecular weight between 3.5 million gr/mol and 10.5 million gr/mol. Compared to low molecular weight Alpolen, Alpolen 1000 is less hard and has higher impact (shock) strengths. It is suitable for areas of use that include continuous impact (shock) situations.

Features: High chemical resistance, low wear, low coefficient of friction. Easy to process in natural color.

Weak Point: Compared with other engineering plastics, it has low contact and mechanical properties, tensile strength, flexible and compression strength.

Technical Values:

Density: 0.96 gr/cm3

Compressive Strength: 300 kg / cm2

Melting Point: 130°C

Bending strength: 300 kg/ cm2

Hardness: m 53 Rockwell Superficial strength: medium

Maximum operating temperature: 80°C

Tensile strength: 260 kg/ cm2

Elongation at Break: 800% Electrical insulation: 2.4 (10 3.2 HZ)

Decomposition by Heat: 55 -80 °C Decomposition factor: 0.005 (10 3.2 HZ)

Water absorption: 0.1% Workability: good

Thermal expansion coefficient: 2.10-4

Light insulation: poor

Coefficient of Friction: 0.20 No contact with food: very good

Resistance to acids: good Resistance to bases: good

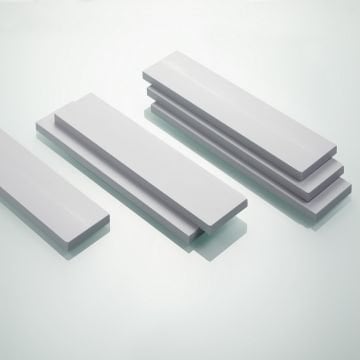

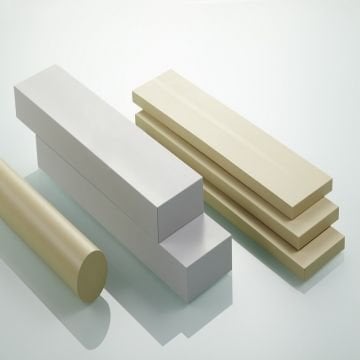

Semi-finished Goods Shipments:

Round Materials: From Ø10 mm to Ø300 mm

Plate Materials: From 5 mm to 100 mm

Special productions are also made.

Alpolen 1000 UHMW PE: Molecular weight 3.5.106 to 10.5.106 g/mol, very high molecular weight

Alpolen 500 HMW PE: Molecular weight 500,000 g/mol. High molecular weight.

Alpolen R 2000 UHMW PE: Very high molecular weight, molecular weight greater than 3.5,106 g/mol

Areas of use:

In coal storage conveyor systems, chutes, chain slides, wear plates, directional bars, bottling machines, conveyor lines, packaging machines, bucket elevators, reduction gears in sliding bearings, star and screw conveyors, cutting and chopping plates, for elevator systems, motor lowering plates, stop valves, pumps and filters, cement, lime, plaster, food and food industry and many other areas.

Alpolen HMW 500

Alpolen 500, with a molecular weight of + / - 500,000, is a harder polyethylene due to its high molecular weight, so it is very suitable for areas of use. It has a low coefficient of friction and excellent machinability.

Weak point:

Compared to other engineering plastics, it has lower thermal and mechanical properties, flexible and compressive strength. When high molecular weight Alpolen 1000 and 500 were compared, it was understood that 1000 material was more resistant to friction and had higher strength at the time of continuous shock.

Impact Resistance Comparison Table:

This table shows that the higher the molecular weight, the higher the impact strength. However, the lower the tensile strength.

Yellow : tensile strength

Grey : impact resistance

Alpolen 2000

Alpolen has a very high molecular weight of > 3.5 million gr/mol. (UHMW Ultra High Molecular Weight) is a UHMW (very high molecular weight) polyethylene material developed by providing flame retardancy, hologen permeability, antistatic properties, outdoor use under UV light, high friction resistance for heavy-duty applications, antibacterial properties (BFR with FDA).

What are the Usage and Selection Differences Between PE-HMW 500 and PE-UHMW 1000 (Alpolen UHMW 1000)? Why should we prefer PE-UHMW 1000?

1) The density of PE-UHMW 1000 is 0.92gr/ cm3 and is lighter than PE-HMW 500 (0.95gr/cm3 ) .

2) PE-UHMW 1000 has 11 times more impact resistance than PE-HMW 500.

PE-UHMW 1000 impact strength: 170 kJ/m 2

PE-HMW 500 15kJ/ m2

3) PE-UHMW 1000's friction resistance (wear resistance) is 4 times more durable than PE-HMW 500. (According to ISO 15527 sand test)

4) PE-UHMW 1000 is 11 times stronger than PE-HMW 500 and 17 times stronger than PE-HD. (In terms of impact resistance)

5) The abrasion resistance of PE-UHMW 1000 is 4 times higher than PE-HMW 500.

Application Examples:

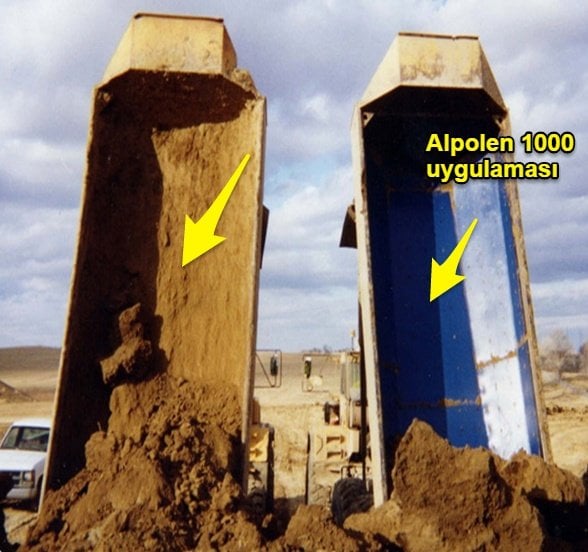

It facilitates the flow of materials with heavy fluidity (cement, lime, sand, etc. that stick to moisture).

For friction profiles and slides in conveyors

Berthing platforms for high impact resistance: Fender