Vehicles with automatic guidance without the need for any operator are called AGV (automated guided vehicles) . They are used in departments such as production, logistics, warehouse and distribution. In addition to reducing human costs, they also prevent work accidents. They also work in manned environments.

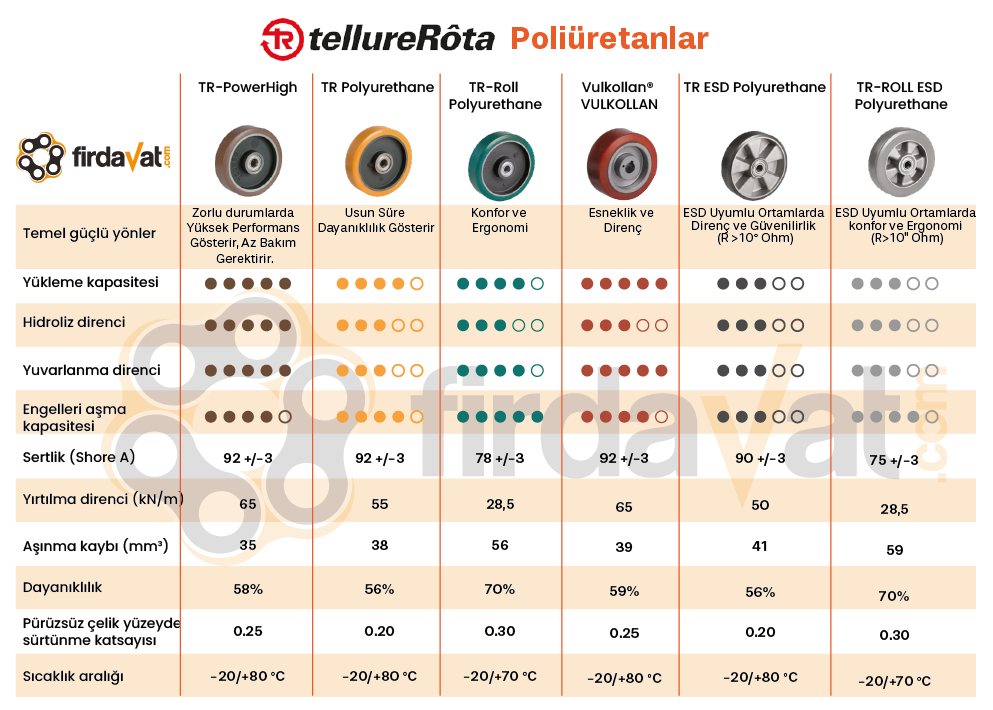

AGV vehicles can carry with a system mounted on them, as well as pulling with the carrying vehicles attached to their backs. While attention is paid to the electronic components and regular maintenance of AGVs, which are used intensively in businesses , the wheels that do the actual carrying work are not selected carefully. The affordable prices selected Wheel failures cause work and time losses in production lines or storage facilities that need to work continuously. New wheels need to be purchased because they break down frequently and their moving systems fail . These wheels, which you think are cost-effective, are actually expensive.

The workflow savings expected from AGVs are disrupted due to the poor quality wheels selected. In short, if the wheel is poorly selected, there is no benefit to using AGVs.

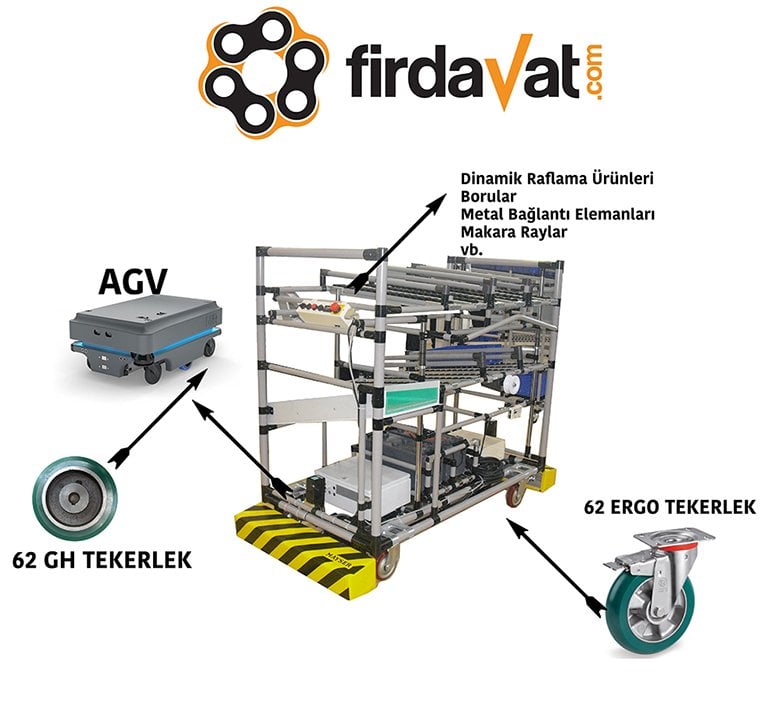

AGV and transport vehicles are used in harmony with dynamic shelving products.