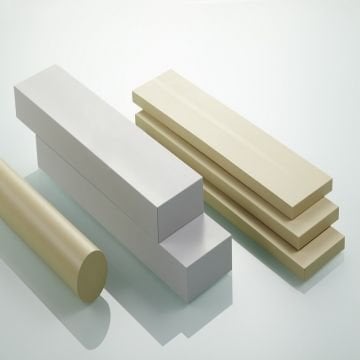

PA 6 POLYAMIDE ROUND Ø60*3000 mm. (10.20kg)

Comment / Read Comments

4.407,74 TL

*With installments starting from 499,75 TL !!

PA6 -POLYAMIDE ROUND Akulon 6-Nylon

Polyamide, obtained by polymerization of caprolactam, is a semi-crystalline polymer and is also known as akulon and nylon (nylon) trademarks. The main reason why this product is known is that it has a good cost-performance relationship.

Features:

Wear resistance: These are plastics with the best working principle in dirty and oily environments and are suitable for harsh environments.

Toughness: High tensile stress and compression strength.

It has high impact resistance and works particularly well with hardened materials.

Working conditions: It maintains its properties even under intense and continuous stress.

Self-lubricating: It can be considered slippery because its coefficient of friction is low.

Does not require lubricants for skid environments.

High aging resistance in various weather conditions.

Color: Natural

Weak Points:

It is not suitable for aqueous environments (hygroscopic). In aqueous environments, its mechanical properties and dimensions change over time by absorbing moisture. It is more durable and efficient in dry environments compared to aqueous environments. POM is generally preferred in aqueous environments. It is easy to process in terms of machining, but it is not suitable for mass production machining. It is not suitable because it causes problems due to the elastic structure of the sawdust.

APPLICATION:

Mechanical: It is preferred for general purpose applications due to its cost-oriented features and low price. It is used to produce multi-purpose gears, wedges, pulleys, wear guides and other mechanical parts. It is used especially in the shipbuilding sector for guides and bearings (large pulleys etc.). Various UV resistance and mechanical properties can be increased with additives.

Food contact: Generally not used in food contact

Use with electricity: It is not preferred because it cannot provide dimensional stability in humid environments.

Chemical: Resistant to inorganic compounds and solvents.

ABRASION RESISTANCE

This diagram shows the weight loss against abrasion below; materials showing lower values are the most resistant.

*Weight values in the options are theoretical and products are invoiced based on the weighed value.

*There may be a ±1-2% difference between the weight values given here and the actual weight values due to tolerance.

*Unit prices vary depending on diameter and thickness.

Be the first to review this product!

Recommended Products