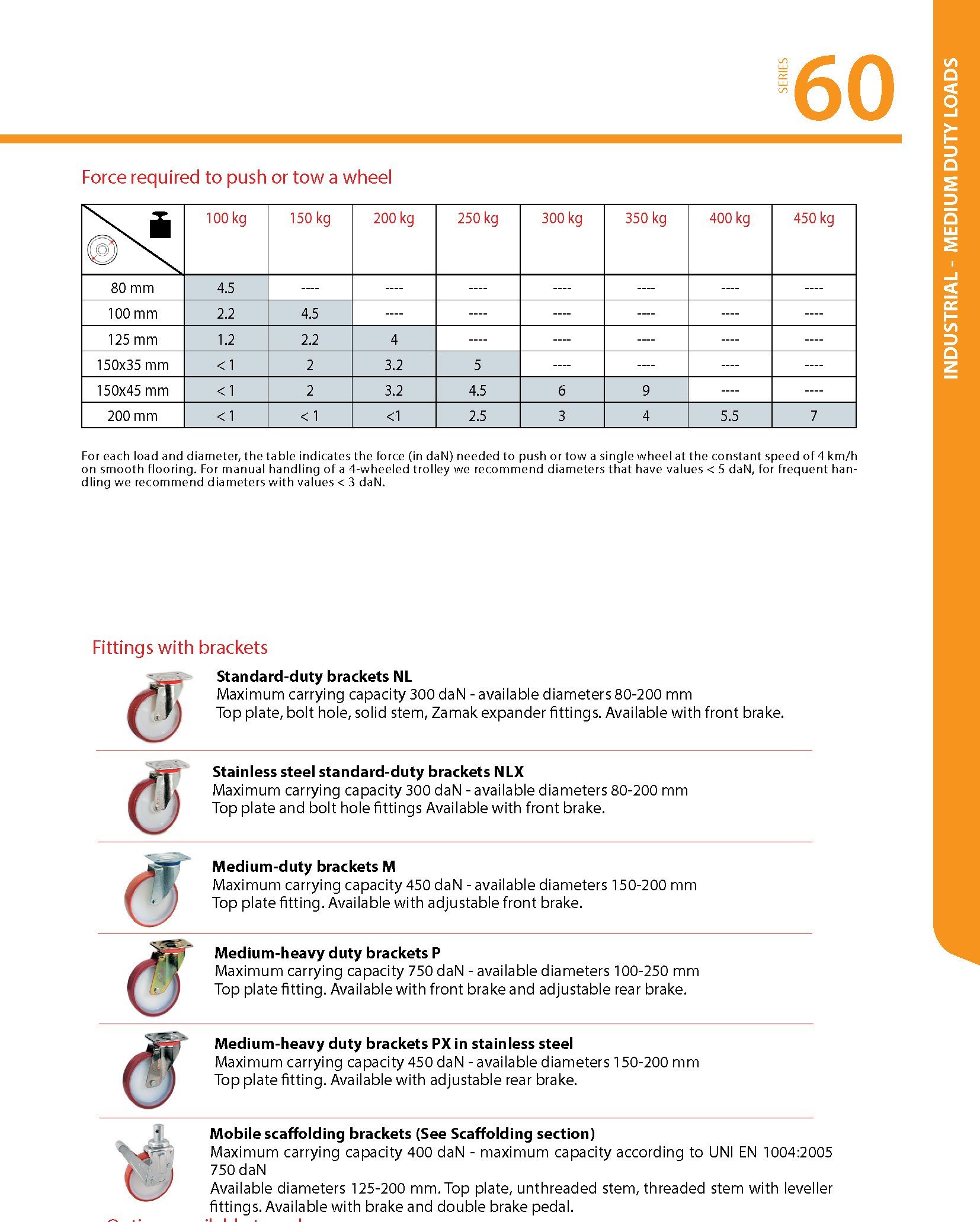

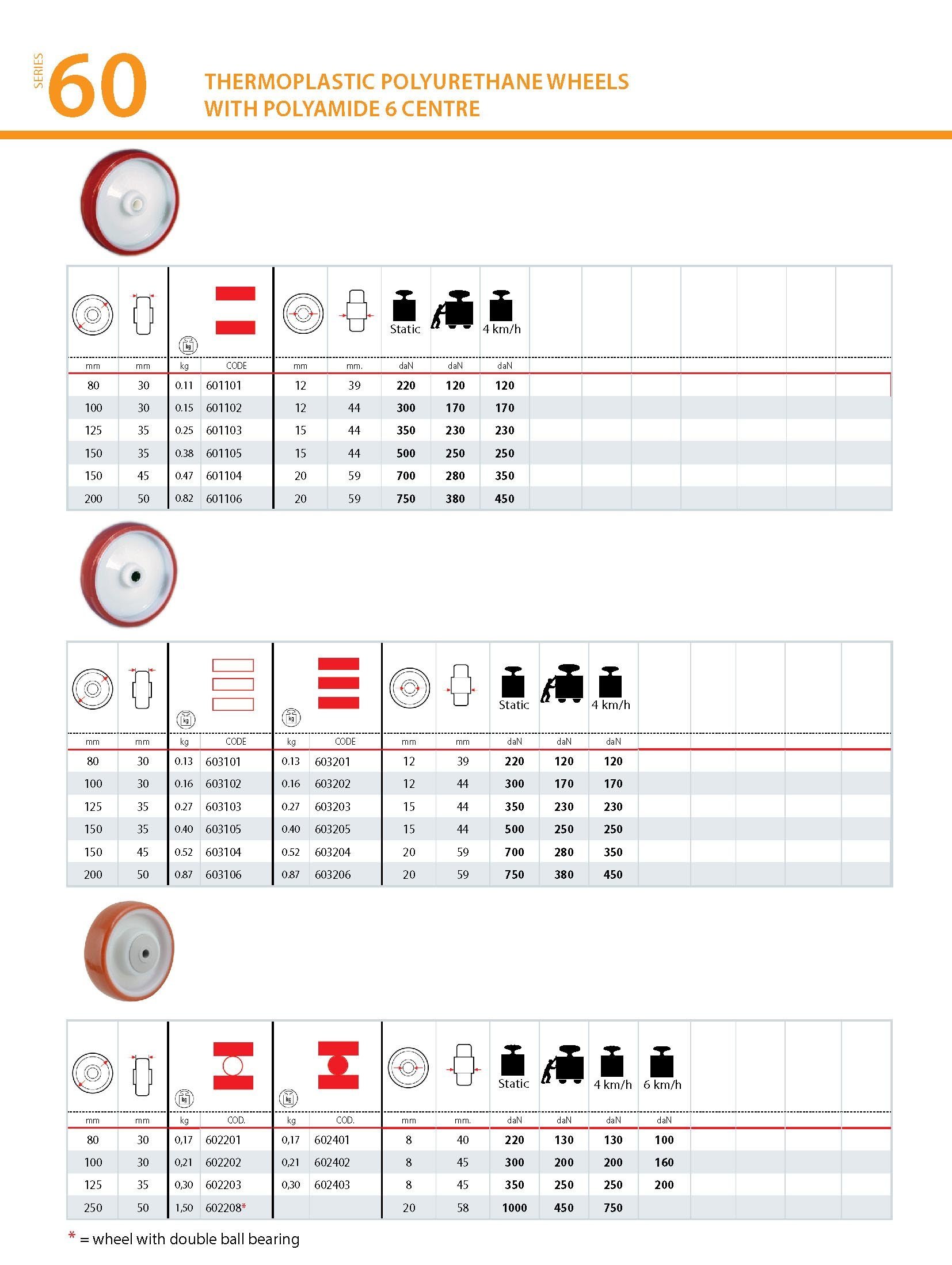

The body of the wheel is made of polyamide and the wheel is produced simultaneously with polyurethane while molding, which gives much better results in terms of physical and chemical unity, compared to the production application where the wheel is poured later.

The bearing geometry that forms the wheel shaft bearing is of different types. Depending on the conditions of use, it can be used directly with a bearingless shaft or a stainless cylindrical roller bearing can be used.

It is molded onto a ball bearing with two covers on the center of the shaft bearing. This bearing acts against dirt and mechanical abrasives, while the reinforced polyamide bushes that protect and guard it act as covers on both sides, ensuring protection against external factors.

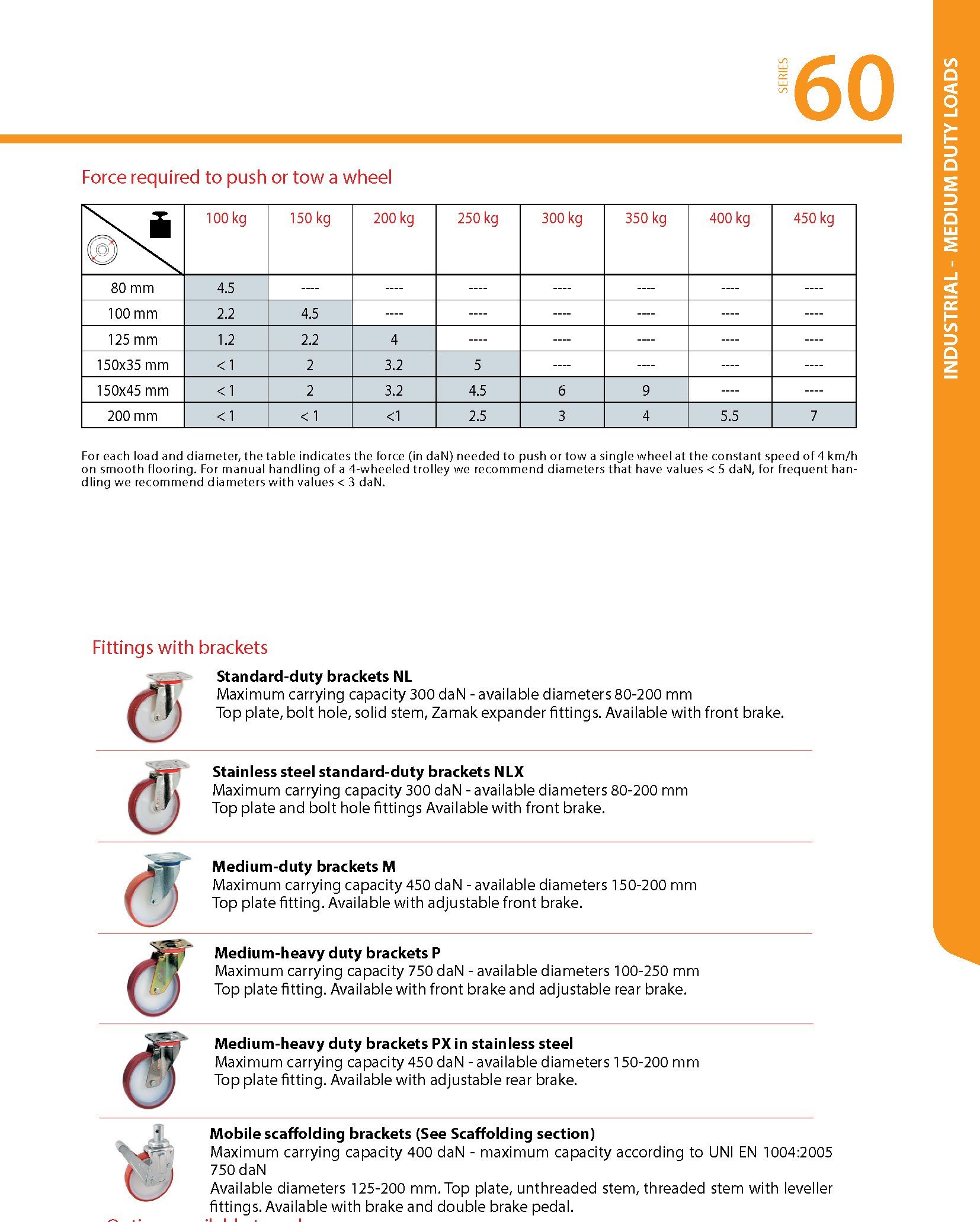

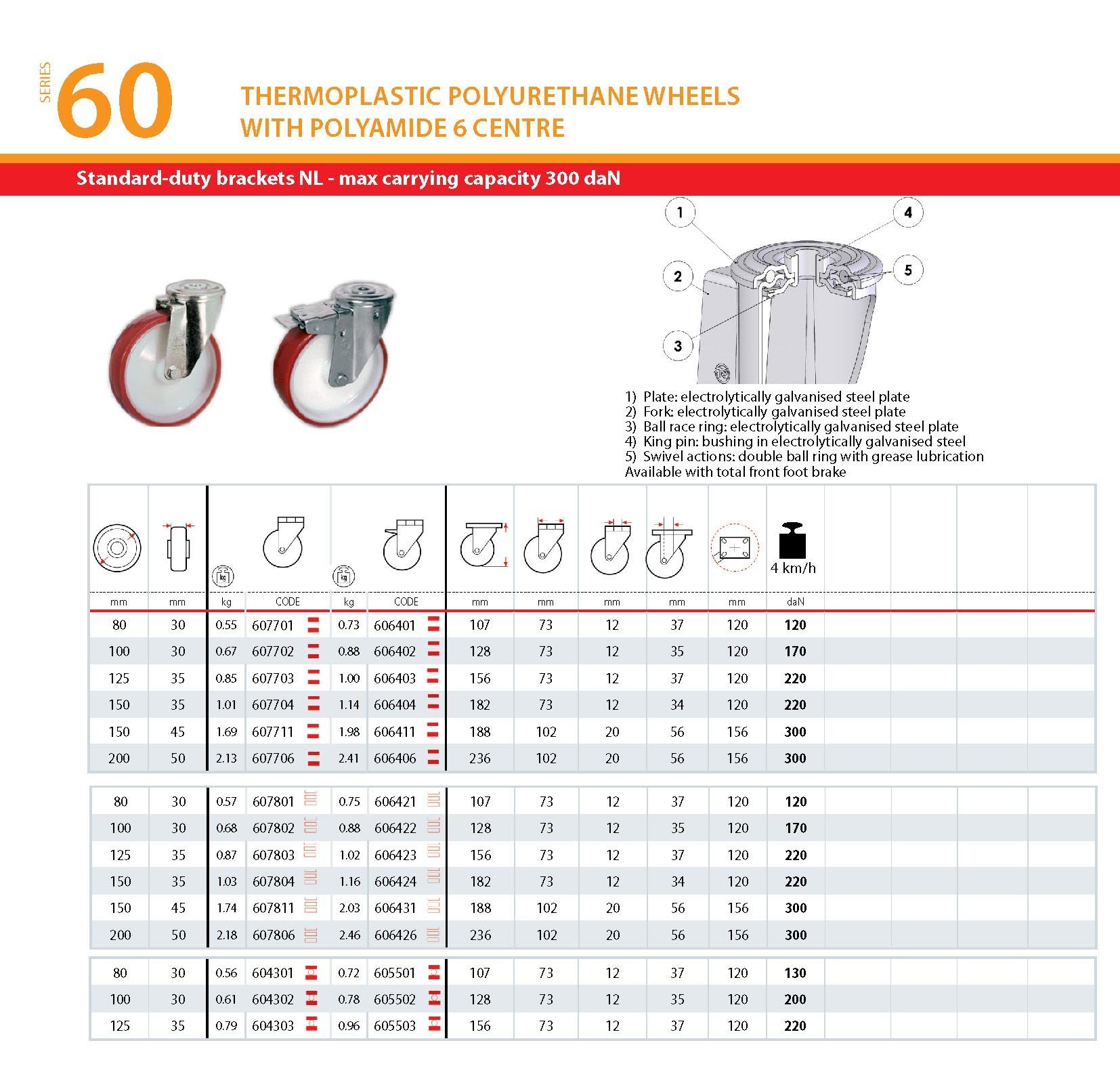

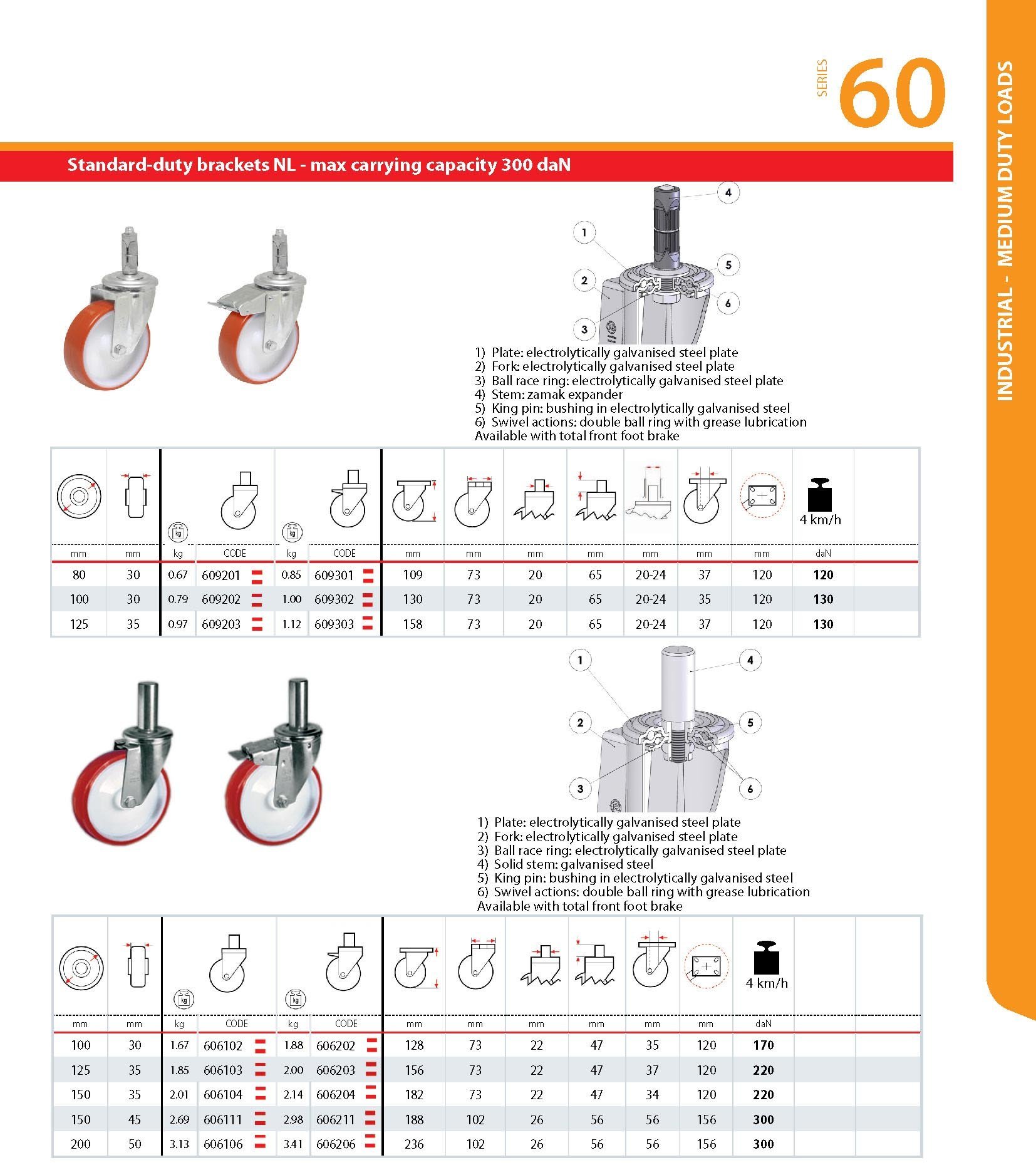

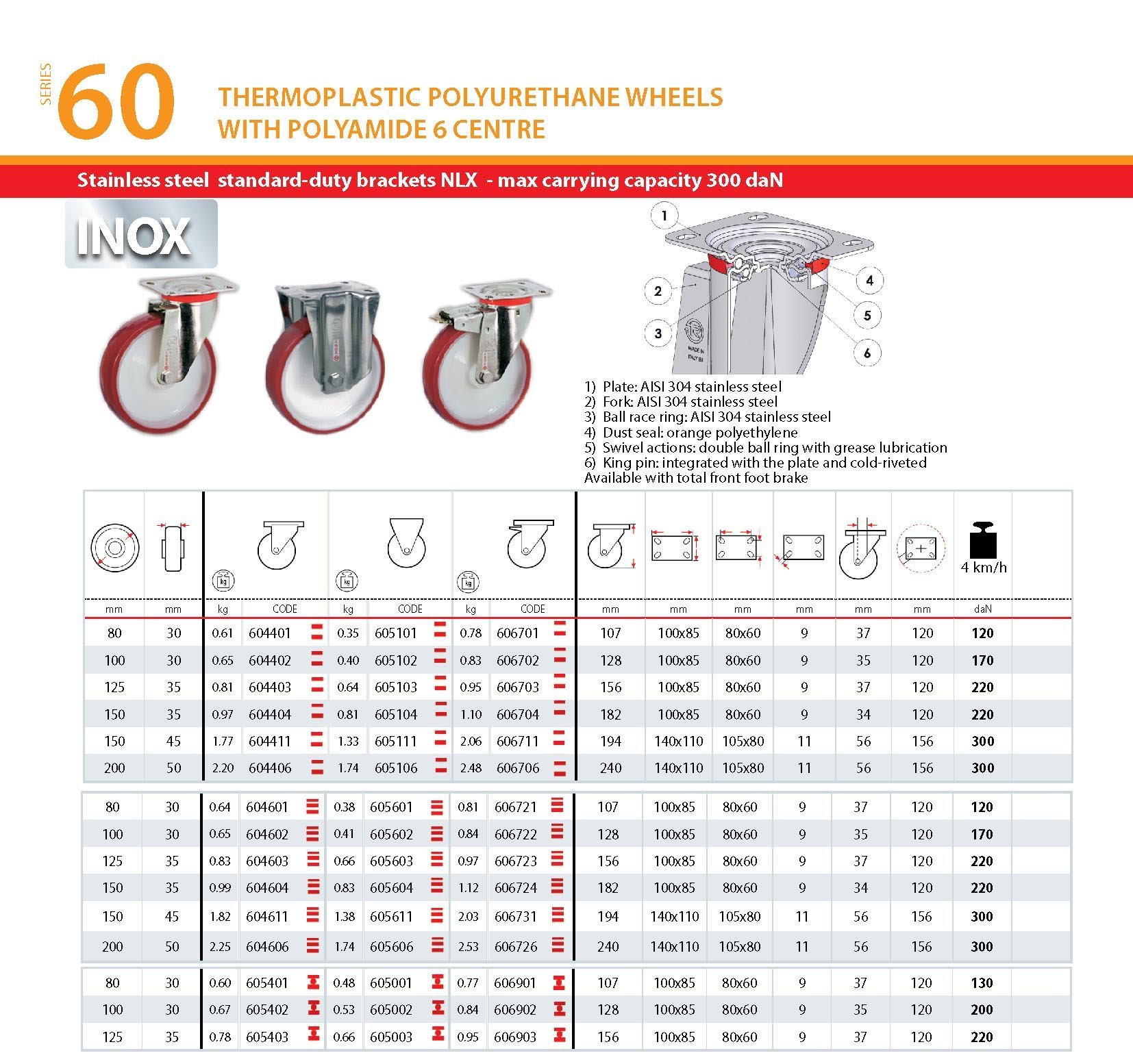

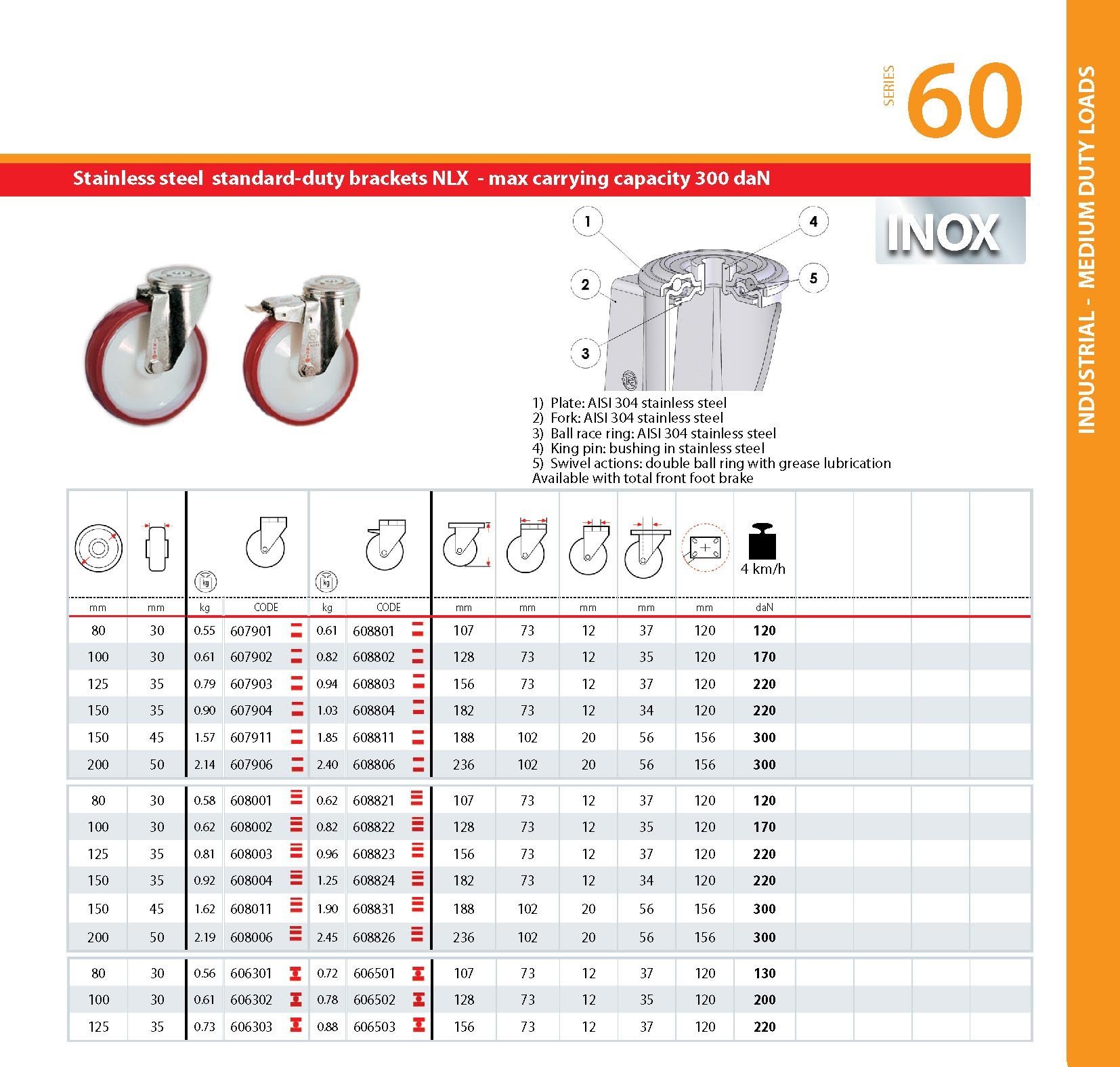

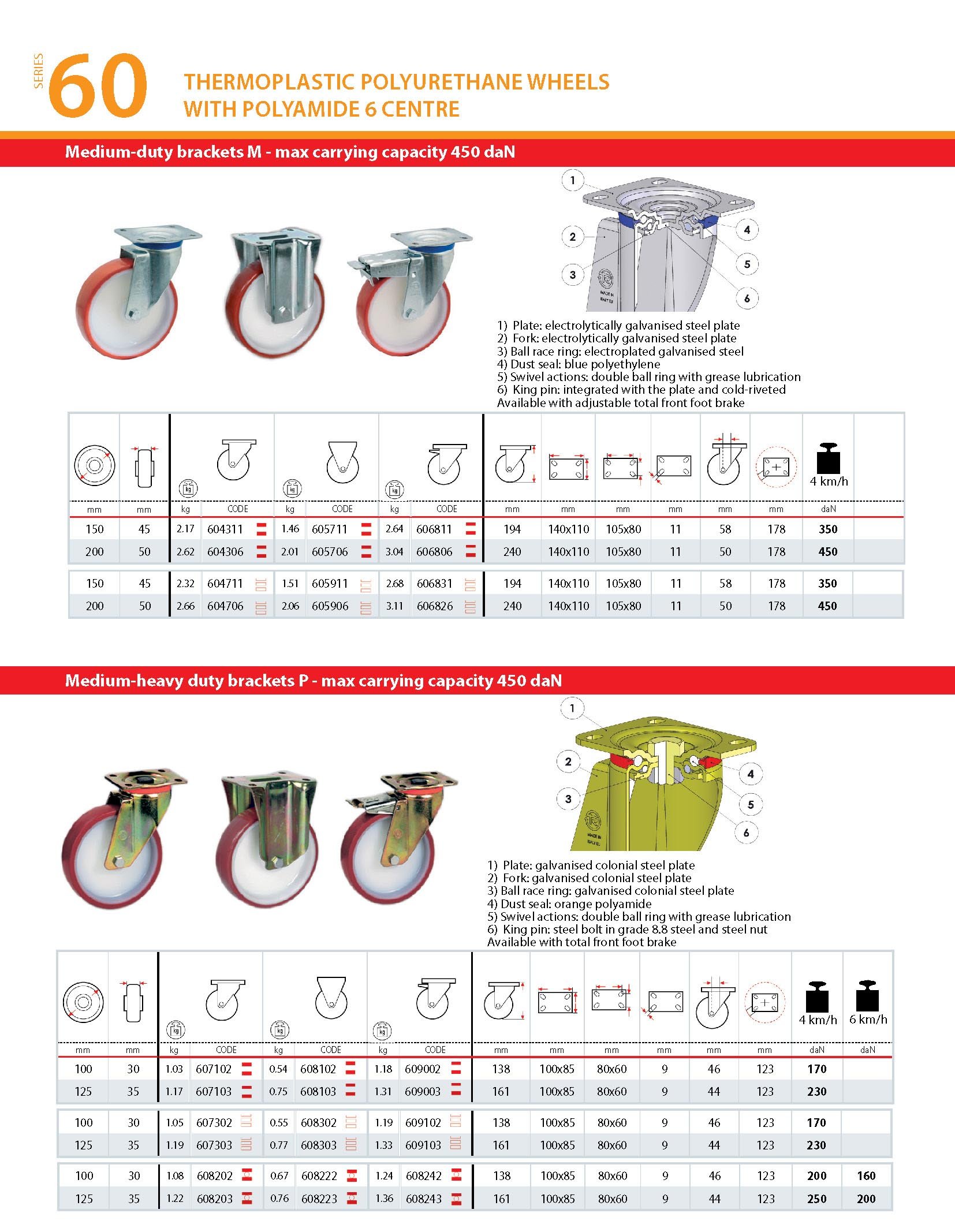

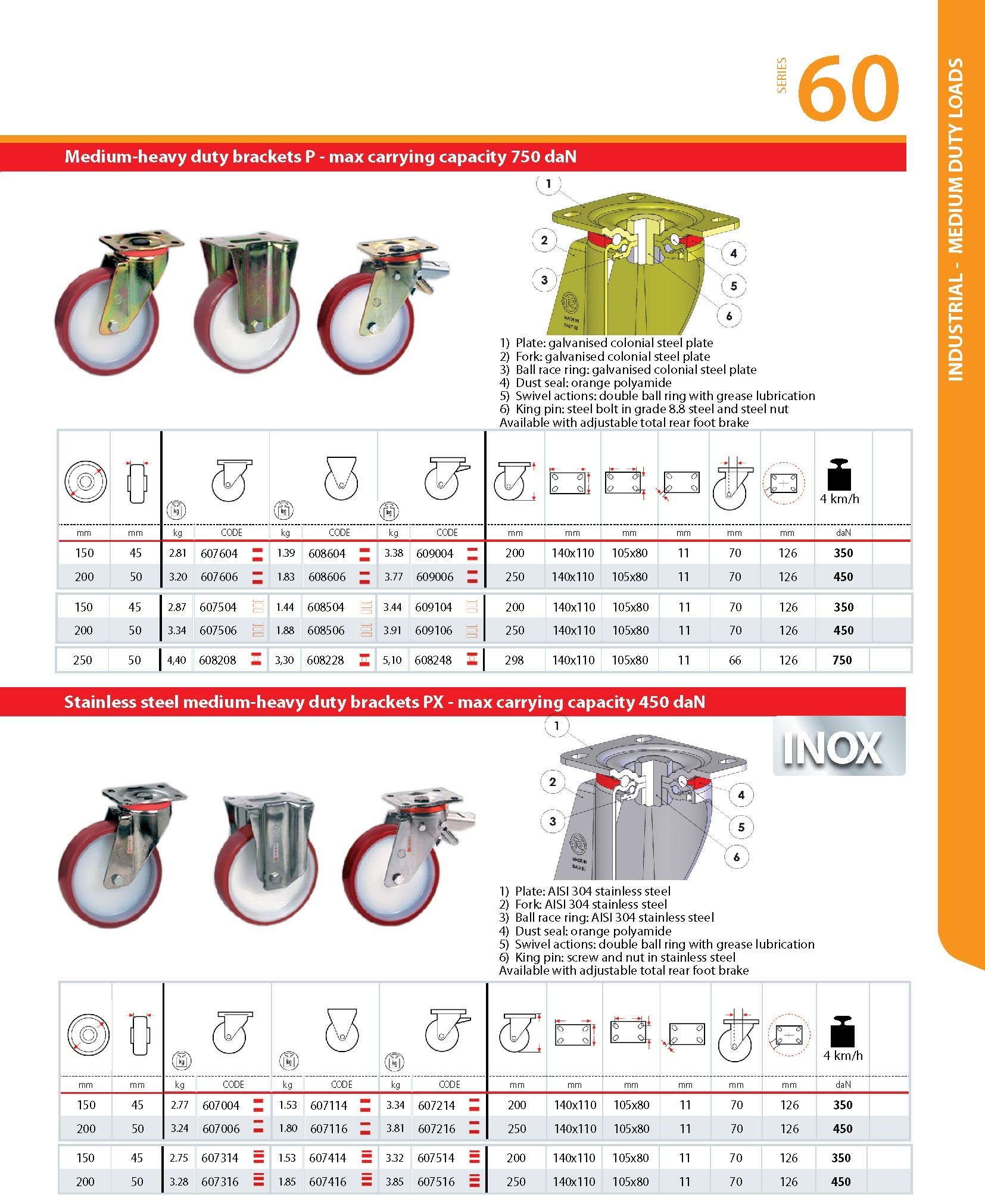

Suitable for continuous transport conditions for medium-level loads on machines and transport trolleys. Ball bearing wheels provide excellent results with a speed of 6 km/h for towing or manual transport.

It can be used for washing and sterilization processes in indoor and outdoor environments. It can also be used for delivery cars, mobile scaffolding and ladders in the food and chemical industry.

It is suitable for cement and ceramic floors and can also survive on slightly uneven ground.

It is resistant to saturated steam, alcohol, glycol, mineral and similar organic acids.

Product Introduction and Review Video